How To Build This Kayak In Single Day

Article By Shorty

This is a story of building a boat in 2.5 hours. This is a VERY FAST method of construction, it is as simple as chine log construction, but you don't have to make all the chine logs -- all you do is cut the sides and glue / nail on a bottom.

I started kicking around the idea of a very small kayak for me, something that was small enough to carry inside the trunk. Would use it as a tender for my larger sailboat, and also as a boat to use in the small fishing ponds. A little drawing time later and I discovered that with 2 of the 8' planks, I could make a kayak that was 5'5" long, 32" beam, and a 350 lb load would have 4.5" freeboard left. Wow, that is a lot of load carrying for such a small boat! So the project went on "the list", and it looked like I wasn't going to build it anytime soon.

Then all of a sudden I got the opportunity to help a friend raise a sunken boat. One catch though, the boat was near the shore, but possibly far enough off that the suction hose of a gas engine pump wouldn't reach, and we would need a small dinghy to carry the pump near the boat, possibly pumping as we towed it to the ramp compensating for a possible hole in the bottom. I didn't have any other boats at the time that would be suitable, so what a perfect opportunity to build this little kayak!

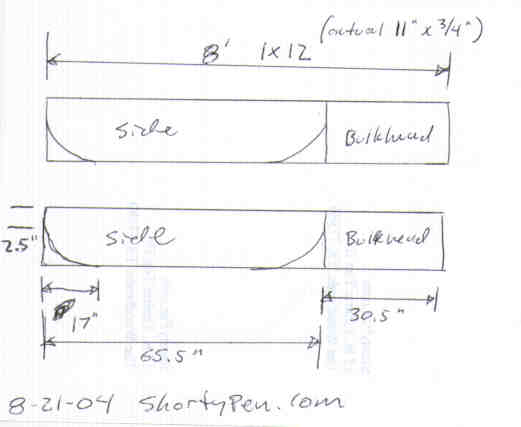

BOAT PLANS

BOAT PLANS Not much to this boat, just get yourself 2 of the 1" x 12" x 8' planks. Cut 30.5" off the ends of each, you will use these for bulkheads. The remaining portion is to make your sides.

With these dimensions, you will end up with a boat that when loaded with 350 lbs, it will have a 6.5" waterline, leaving you 4.5" of freeboard left. If you want a boat that will carry more weight, consider making the sides longer. 32" is a really good dimension for the beam, if you want to paddle it, I would suggest keeping it that same width.

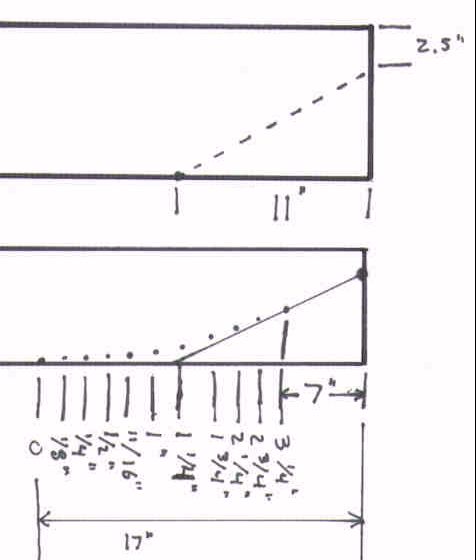

The Curves

The CurvesTo make the curve in the end of the sides, start by drawing a straight line that starts from 2.5" down, and goes to 11" back on the bottom. Next you will draw a series of tick marks, starting from 7" back and 3-1/4" from the bottom, and continue till you get to the last mark at 17" back. Each of the tick marks are 1" apart. Connect the dots, cut the curve, and that is the tightest bend that I could make 1/4" BC pine plywood bend around.

Here I have cut the ends off the planks and saved them for bulkheads later.

Also I cut the curves in the ends of the sides.

Here I have cut the ends off the planks and saved them for bulkheads later.

Also I cut the curves in the ends of the sides.

Glue and screw the transoms on, they really are just 2.5" pieces.

I didn't even cut a bevel in them, just 2.5" x 3/4" strip of wood.

Glue and screw the transoms on, they really are just 2.5" pieces.

I didn't even cut a bevel in them, just 2.5" x 3/4" strip of wood.

The bottom is 6' long, from end to end around the curves by 32" wide.

I didn't have a piece of 1/4" plywood that big in stock, so I used a couple of smaller pieces, here is the bigger one.

Lots of titebond II glue on the sides, if the glue isn't squeezing out of the joint and dripping down the sides, then you aren't using enough glue.

I figure that 50% loss of glue to dripping and mopping up with paper towels is perfectly acceptable, especially at how cheap titebond II is.

The nails I use are 3/4" bronze ring shank nails, they hold like a screw, but are fast to install like a nail, and if you need to cut thru the board later they won't mess up your saw blade.

The bottom is 6' long, from end to end around the curves by 32" wide.

I didn't have a piece of 1/4" plywood that big in stock, so I used a couple of smaller pieces, here is the bigger one.

Lots of titebond II glue on the sides, if the glue isn't squeezing out of the joint and dripping down the sides, then you aren't using enough glue.

I figure that 50% loss of glue to dripping and mopping up with paper towels is perfectly acceptable, especially at how cheap titebond II is.

The nails I use are 3/4" bronze ring shank nails, they hold like a screw, but are fast to install like a nail, and if you need to cut thru the board later they won't mess up your saw blade.

I nailed the flat part on first, then leaned on the plywood and nailed along the way to get the plywood to hold it's curve.

I am often asked by new builders how I was able to bend the plywood.

Well, if you try to bend it in the air, it is difficult.

But if you are bending the plywood around a form (like the sides of this boat), it will adhere to the form.

The most important thing to do is bend it a little, and put in a nail, then bend some more, put in another nail.

This boat uses a very simple curve that is very easy to get the 1/4" plywood to match.

I nailed the flat part on first, then leaned on the plywood and nailed along the way to get the plywood to hold it's curve.

I am often asked by new builders how I was able to bend the plywood.

Well, if you try to bend it in the air, it is difficult.

But if you are bending the plywood around a form (like the sides of this boat), it will adhere to the form.

The most important thing to do is bend it a little, and put in a nail, then bend some more, put in another nail.

This boat uses a very simple curve that is very easy to get the 1/4" plywood to match.

The middle was flexing up a bit, so I put in a couple of screws to hold it down.

Later I'll remove these screws.

The middle was flexing up a bit, so I put in a couple of screws to hold it down.

Later I'll remove these screws.

I put the other half of the bottom on, and it is really looking like a boat.

I put the other half of the bottom on, and it is really looking like a boat.

To join the bottom pieces, I put a butt strap across the inside which is really just a strip of plywood that is glued on.

The water bottles are to put some pressure on the joint when it is curing.

To join the bottom pieces, I put a butt strap across the inside which is really just a strip of plywood that is glued on.

The water bottles are to put some pressure on the joint when it is curing.

To save time, I didn't cut a bevel into the transoms, I just used rectangular boards.

I sorta missed on this one, and created an even bigger gap.

No problem, I am going to just tape up the seam, and put an epoxy fillet in there.

To save time, I didn't cut a bevel into the transoms, I just used rectangular boards.

I sorta missed on this one, and created an even bigger gap.

No problem, I am going to just tape up the seam, and put an epoxy fillet in there.

First thing I need is a stick with a round end, sort of like a large tongue depresser.

I chuck a 5" sanding disk into my drill press and use it like a bench disk grinder.

Now that I think of it, I probably spend more time using my drill as a sander, than for drilling.

I sand all sorts of stuff like this, really is handy to use.

First thing I need is a stick with a round end, sort of like a large tongue depresser.

I chuck a 5" sanding disk into my drill press and use it like a bench disk grinder.

Now that I think of it, I probably spend more time using my drill as a sander, than for drilling.

I sand all sorts of stuff like this, really is handy to use.

Next I need to figure which filler I am going to use.

I only had a little bit of talc left, and I have a couple of repairs on my fiberglass boat to do, so I didn't want to use that up.

So I took some sawdust and ran it thru my blender.

I mixed this 50/50 with wheat flour to make it less rough.

I have previously used 100% wheat flour for fillets, and while it is VERY smooth, it is also a bit on the lumpy side and takes a lot of flour.

The sawdust will help bulk up the filler quicker.

Next time I think I'll use 70% flour, because the 50/50 mix was a little rough.

Next I need to figure which filler I am going to use.

I only had a little bit of talc left, and I have a couple of repairs on my fiberglass boat to do, so I didn't want to use that up.

So I took some sawdust and ran it thru my blender.

I mixed this 50/50 with wheat flour to make it less rough.

I have previously used 100% wheat flour for fillets, and while it is VERY smooth, it is also a bit on the lumpy side and takes a lot of flour.

The sawdust will help bulk up the filler quicker.

Next time I think I'll use 70% flour, because the 50/50 mix was a little rough.

Give it a good shake, and that is some good looking filler.

Notice how there is less of the mixed filler, than of the original unmixed portions.

What is happening is that the flour is filling in the space between the sawdust, so when mixed it is a smaller volume.

Give it a good shake, and that is some good looking filler.

Notice how there is less of the mixed filler, than of the original unmixed portions.

What is happening is that the flour is filling in the space between the sawdust, so when mixed it is a smaller volume.

Mix enough into the epoxy that it makes a peanut butter like substance.

I mixed in a little too much filler, but it will still work OK.

Mix enough into the epoxy that it makes a peanut butter like substance.

I mixed in a little too much filler, but it will still work OK.

Smear some into the joints, and preso they are done.

Smear some into the joints, and preso they are done.

I didn't do the inside of the chines at this time, I was in a hurry to get the boat done and on the water. Later I'll come back and fillet those too.

To stiffen up the ends, I screwed on a couple of scrap pieces of plywood as decks.

Later I'll add in the bulkheads and fully deck over the bow and stern so they are floatation chambers.

To stiffen up the ends, I screwed on a couple of scrap pieces of plywood as decks.

Later I'll add in the bulkheads and fully deck over the bow and stern so they are floatation chambers.

Now for the skid.

The skid is an important structural member, it prevents the bottom from "oil canning" - that is when the bottom flexes around.

My first skid was 1/2", but when I tried to bend it around the bottom, it snapped right off.

Now for the skid.

The skid is an important structural member, it prevents the bottom from "oil canning" - that is when the bottom flexes around.

My first skid was 1/2", but when I tried to bend it around the bottom, it snapped right off.

The next skid I made was only 1/4" thick, and it was able to take the curve just fine.

Lots of glue and screwed right thru the skid into the bottom.

Later I pulled out the screws and filled up the holes with thickened titebond II glue.

The next skid I made was only 1/4" thick, and it was able to take the curve just fine.

Lots of glue and screwed right thru the skid into the bottom.

Later I pulled out the screws and filled up the holes with thickened titebond II glue.

One quick coat of latex exterior house paint on the outside and bottom of hull, a total of 2.5 hours of labor and I take my first spin on the water !!!

One quick coat of latex exterior house paint on the outside and bottom of hull, a total of 2.5 hours of labor and I take my first spin on the water !!!

Wasn't sure if I was going to like it, so it was nice to stop and take it for a test paddle. Not only do I like it, I love it. I can really see how this is going to be a fun boat to use.

Lots of other details to finish up, starting with airboxes to make it self rescuable....